architect: Archi-Union Architects

location: Shanghai, China

year: 2010

When we face the old complex with three warehouses and try to change its use to be an office for innovative working, it is the frugal building aesthetic and a simple and practical process that we pursue in design. The “Wu Wei Space” innovative industrial zone was initially the Shanghai Huafeng No. 1 Cotton Spinning Mill established in the 1940’s which had been called a gardenesque factory, and one can still see the left over stacks, trees, etc. With the city of Shanghai going into the post-industrial society, the once prosperous factory was shut down and has now been replaced by an innovative industrial zone, step by step. Artists are keen on the north-facing dormers, row upon row, high stacks made by red black brick and steel building frames. Photographic teams shooting wedding photos keep pouring in and the scenes consist of brides and grooms marking their own special occasion. During the design period, our thinking was direct: use the most economic material and frugal method to achieve our building concept. In the whole design of this innovative zone, we used different ways to realize different spaces for interiors and exteriors. Firstly, it is about 5m~7.5m in height in the inner space which obviously needed to be divided and shrunk for the relatively small studio. So, the division depended on several factors in terms of the effective space under air ventilation, the balance between space for exhibition and office, the enclosing wall, turned wall line, lifted stairs and the change of parameters. All this helped to define the meaning of a simple space. The non-linear spaces express themselves in a linear style by parameterized drawing; the sectioned drawings realized the various atmospheres intended for spaces.

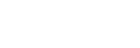

The enclosing wall, made with the economical concrete airbrick; shows a nature of silk. The entire process follows precisely the traditional way of constructing a wall. First; building a concrete frame as support, then laying the air bricks above., Those, airbricks are widely used in areas of rural China and industrial factories. We hoped to create a new, different form, from traditional materials by using new technology, and refresh the airbrick with a youthful vigor. The rough feeling of the material finely matches the old factory.

However, the gap between design and building is the main difficulty in front of us which is inevitable in the environment of China. The introduction of hardware is lagging behind the expanse of software, even parameterized designs could be realized, the assistant directly from computer can’t be done. Besides, the large number of migrant workers in China possess only basic construction skills and would benefit from a specialized management mode to help establish a parameterized achievement. We adopted the strategy of parameterized design with basic construction skills to compensate the low availability of skilled labor. Furthermore, creating templates for construction at varyng angles for the bricks allowed workers to achieve a controlled construction method.

This practice of parameterized design is an emergent reflection to the current situation, which is far different from the one growing in western countries. The temptations of low price labor, poor skills and the lack of matched device— is keeping us behind in seeking the fusion between design and building. However, we are convinced that in such a special situation, China could improve the profound thought to include the methods of design and the logic of building for architects. This kind of thinking could be low cost as well as creative.